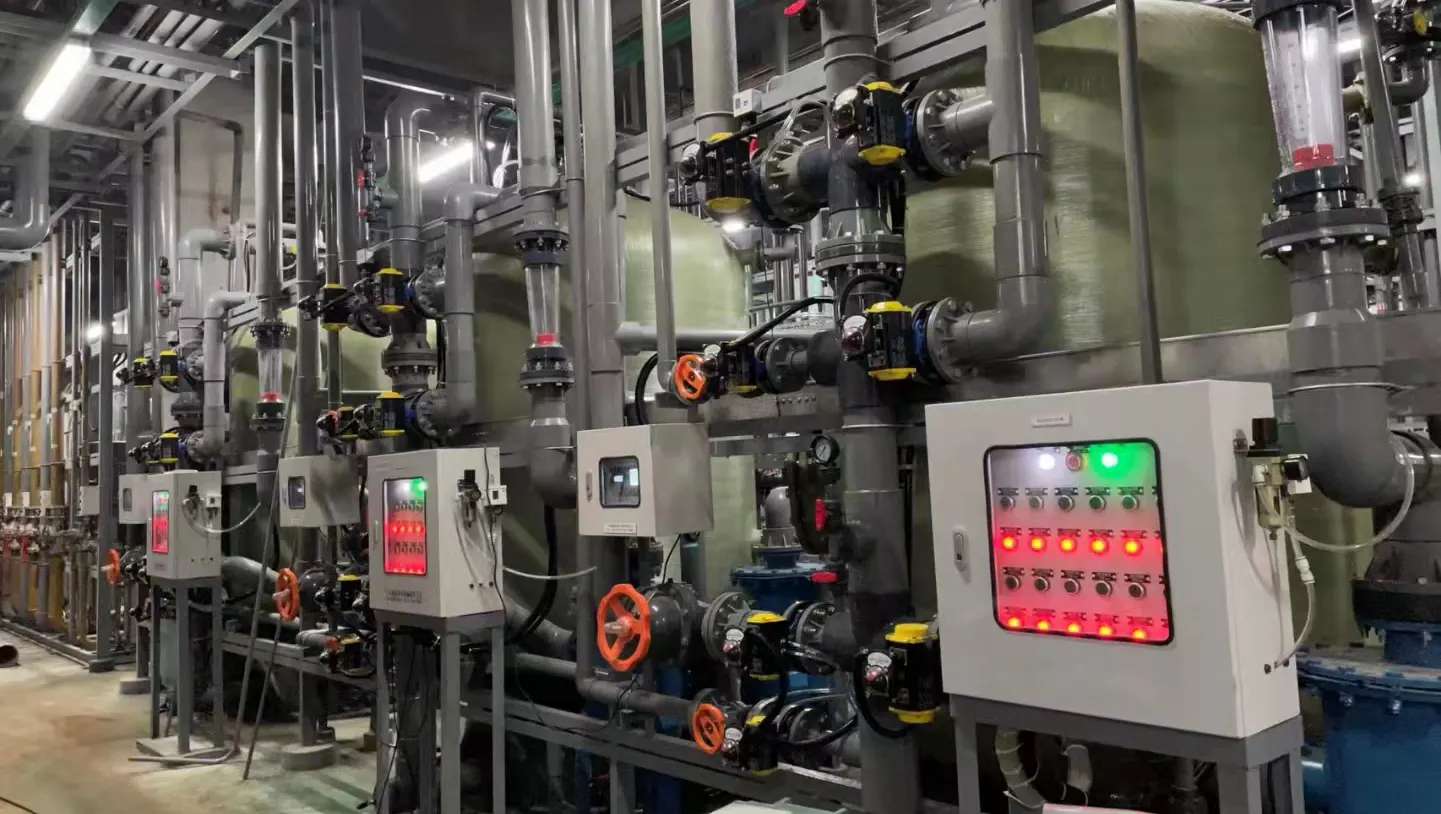

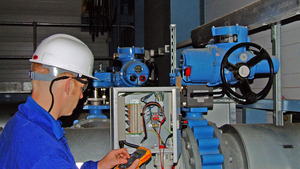

Electric actuators:

Two movment code: angular stroke and linear stroke. It often equipped with ball valves, butterfly valve, globe valve and gate valves; AC or DC current as the driving energy; The advantage is fast signal transmission speed, long transmission distance, easy centralized control, high sensitivity and precision, easy to cooperate with electric adjustment instruments, simple installation and wiring. The disadvantage is that the structure is complex, the thrust is small, and the average failure rate is higher than that of the pneumatic actuator. It is suitable for places with low explosion-proof requirements and lack of air sources.

Pneumatic actuators:

The actuator and adjustment mechanism of the pneumatic actuator are a unified whole, and the actuator has a membrane type, a piston type, a fork type and a rack and pinion type.

- The piston type has a long stroke and is suitable for occasions requiring greater thrust;

- The membrane type has a small stroke and can only directly drive the valve stem.

- The fork-type pneumatic actuator has the characteristics of large torque, small space, and the torque curve is more in line with the torque curve of the valve, but it is not very beautiful; it is often used on valves with high torque.

- The rack-and-pinion pneumatic actuator has the advantages of simple structure, stable and reliable action, and safety and explosion protection. It is widely used in the production process with high safety requirements such as power plants, chemical industries, and oil refining.

Comparison of pneumatic actuators and electric actuators:

1. In terms of technical performance, the advantages of pneumatic actuators:

- Good working environment adaptability, especially in the harsh working environment such as flammable, explosive, dusty, strong magnetism, radiation and vibration, it is superior to hydraulic, electronic and electrical control.

- Quick action and quick response.

- The load is large and can be adapted to the application of high torque output (however, the current electric actuator has gradually reached the current pneumatic load level).

- The motor is easily damaged when the stroke is blocked or the valve stem is tied.

2. The advantages of electric actuators mainly include:

- There is no need to install and maintain various pneumatic pipelines.

- The load can be maintained without power, while pneumatic actuators require continuous pressure supply.

- The electric actuator has no risk of “leakage” and has high reliability. The compressibility of air makes the stability of the pneumatic actuator slightly worse.

- Compact structure and small size. Compared with pneumatic actuators, electric actuators are relatively simple in structure. A basic electronic system includes actuators, three-position DPDT switches, fuses and some wires, which are easy to assemble.

- The driving source of the electric actuator is very flexible, and the general vehicle-mounted power supply can meet the needs, while the pneumatic actuator requires an air source and a compression drive device.

- Because no additional pressure device is required, the electric actuator is quieter. Usually, if the pneumatic actuator is under heavy load, a silencer should be installed.

- In pneumatic devices, it is usually necessary to convert electrical signals into pneumatic signals and then into electrical signals. The transmission speed is slow, and it is not suitable for complex circuits with too many components.

- Electric actuators are superior in control accuracy.

Electric actuators are poor in safety and explosion-proof, the motor does not move quickly enough, and the motor is easily damaged when the stroke is blocked or the valve stem is tied. However, because the actuator itself has the servo function, there is no need for an external servo amplifier; it can be equipped with an overload protection unit; any positive and negative actions can be selected; the valve self-locks after the power is off; the motor has a temperature protection switch to protect the motor from burning. Electric actuators are constantly improving and there is a trend to expand their applications.

--- END ---